| Green House Propagation | | A green house is a framed structure covered with glass or UV stabilized polyfilm where crops could be grown under partially or completely controlled environment. The transparent cladding material allows the solar radiation to enter in the green house generally remains 10-150C more than outside even during winters. A Green house permits round the year cultivation and growing off season vegetables in hilly regions even during winters and helps in supplementing the income of farmers. It is found that the yield in the green house is five to six times higher than in open fields. The crops mature faster. In high altitude regions the growing season can be extended. An attached green house can also be used for space heating of houses during winters. |

Advantages

Increases carbon-dioxide level, leading to better photosynthesis.

Plant growth is improved and crops mature faster.

Use of water is optimized due to reduced evapo-transpiration, upto

Use of UV stabilized film , filters out harmful ultra-violet rays.

Crop is protected from rain, hail stones, storm , wind & frost in winter.

Crop is saved from birds , monkeys and stray animals.

Incidence of diseases and pests is reduced.

|

| Types of Green House | 1. Tunnel Type Green House | 2. Gable Type Green House | | 3. Lean to Wall Green House | 4. M.S. Lean to Wall Green House |

M.S. lean to wall green house |

Gable type green house |

Tunnel type pipe frame green houses |

Tunnel type pipe frame green houses

|

Bamboo frame tunnel type greenhouse

|

Lean to wall green house attached to ATC office |

Bamboo frame tunnel type greenhouse |

| Forest Waste Biomass | | Pine Needles and Other Forest waste Biomass |

Introduction

Millions of tons of biomass gets generated from forest residues especially pine needles. These pine needles if not removed from the ground can cause a lot of damage to the environment due to their highly inflammable nature. A pine tree trunk is heat resistant, hence in case of a forest fire, pine trees survive the fire but in the process destroy the growth of other plant species. Dry pine foliage also stops water from being absorbed by the soil and thus causes the depletion of ground water table. Fallen dry pine foliage blocks the sunshine reaching the ground and thereby stops the growth of grass which the cattle feed upon. Although dry pine needles and other forest residues have high cauliflower value, this biomass cannot be used directly due to its low bulk density and high moisture content. |

Equipments Required

1) Drum with lid, 200 Lit.

2) Stove for burning Briquettes.

3) Mould for casting Briquettes.

|

Material Required

1) Pine Needles

2) Clay

|

Preparation of the Briquettes

Dry the biomass collected in open air for ten days to reduce moisture content of the material. Carbonization: For carbonization, loosely pack the collected biomass into the Drum. The Drum will accommodate ~25 kg dry biomass. After loading the biomass into the drum in layers, close top of the drum with metal lid after removing conical chimney. The briquettes will take 2-4 days for drying. These briquettes burent in special design stove. After mixing the carbonised biomass with clay soil and adding water in the mixture , it can be converted into briquettes with the help of mould . |

Methods

Biomass collection – Drying – Carbonization –Binding material – Briquetting -- Drying

Time cycle of one batch carbonization

Process -- duration

Loading -- 30 minutes

carbonization -- 60 minutes

Unloading -- 30 minutes

Total process time -- 7 hrs

|

| |

Trainees Casting Pine Briquettes

|

Training Programme on Pine Briquetting

| | | | |

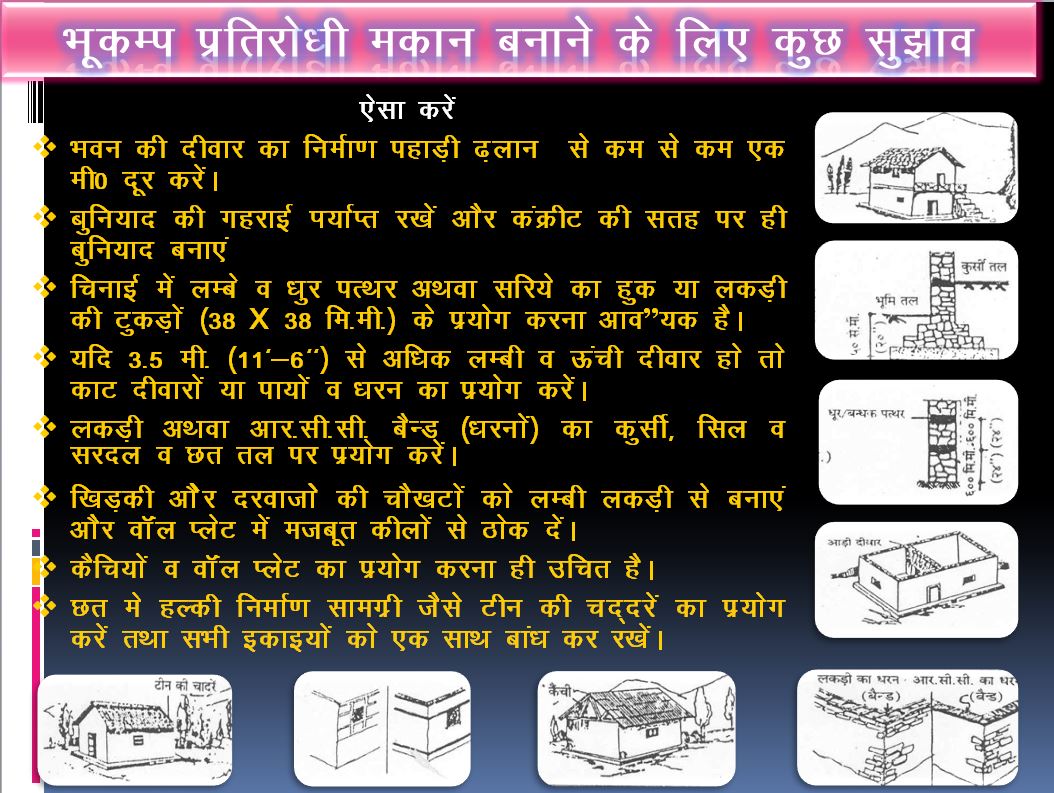

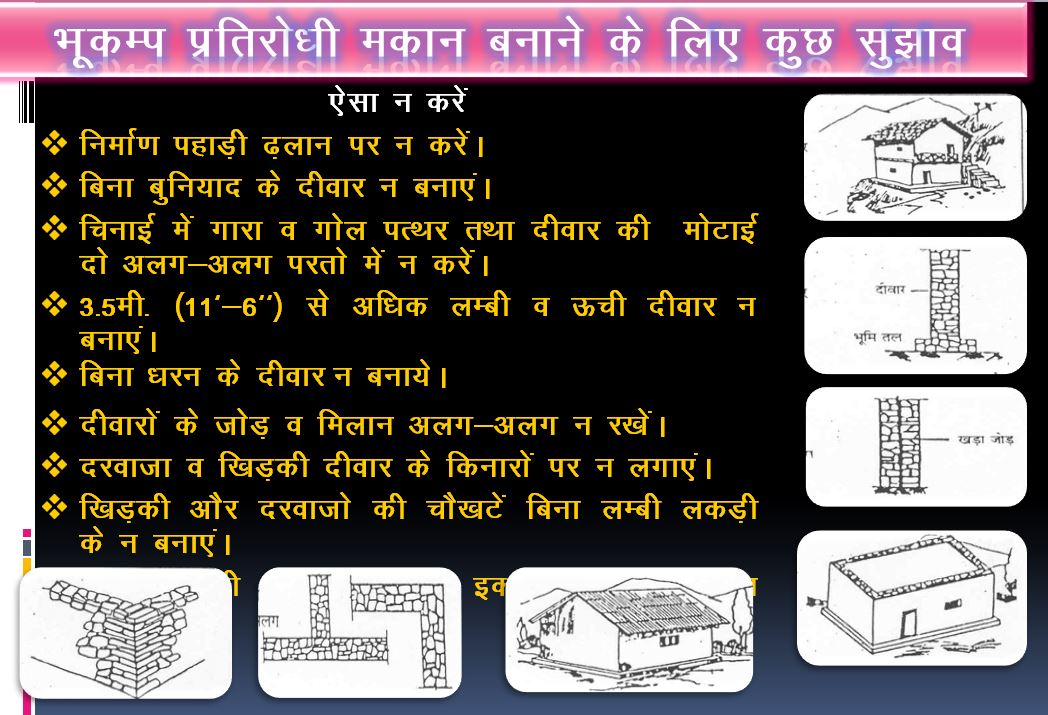

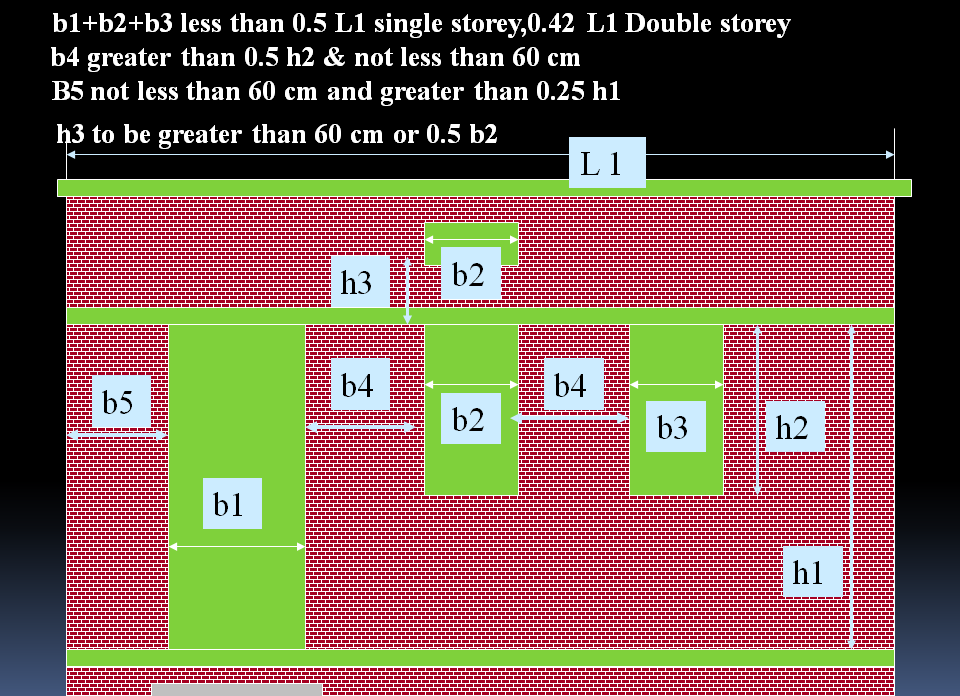

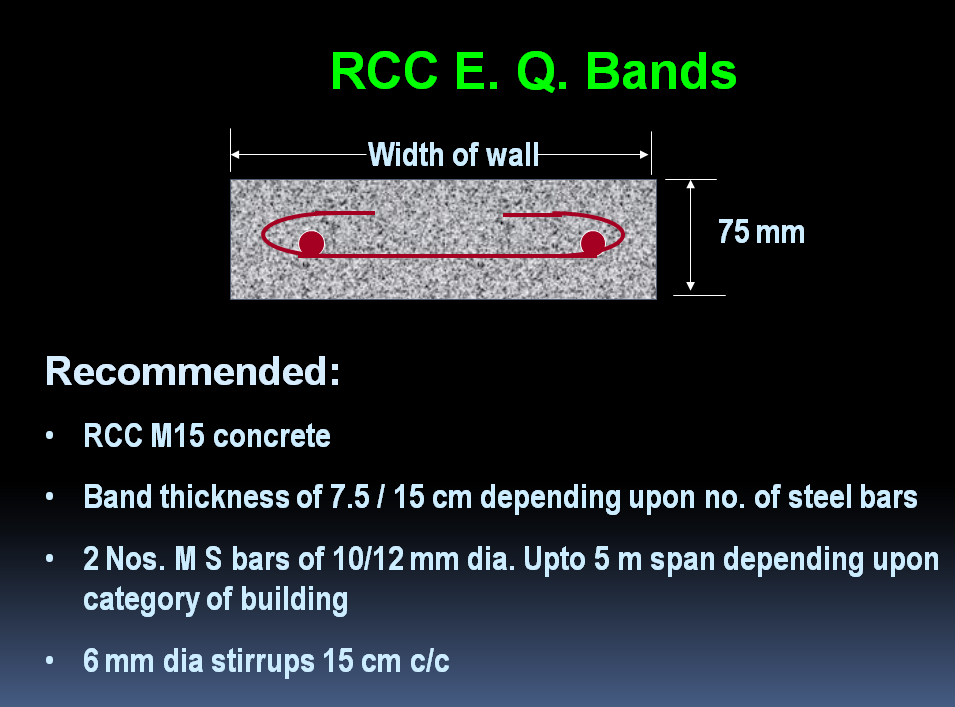

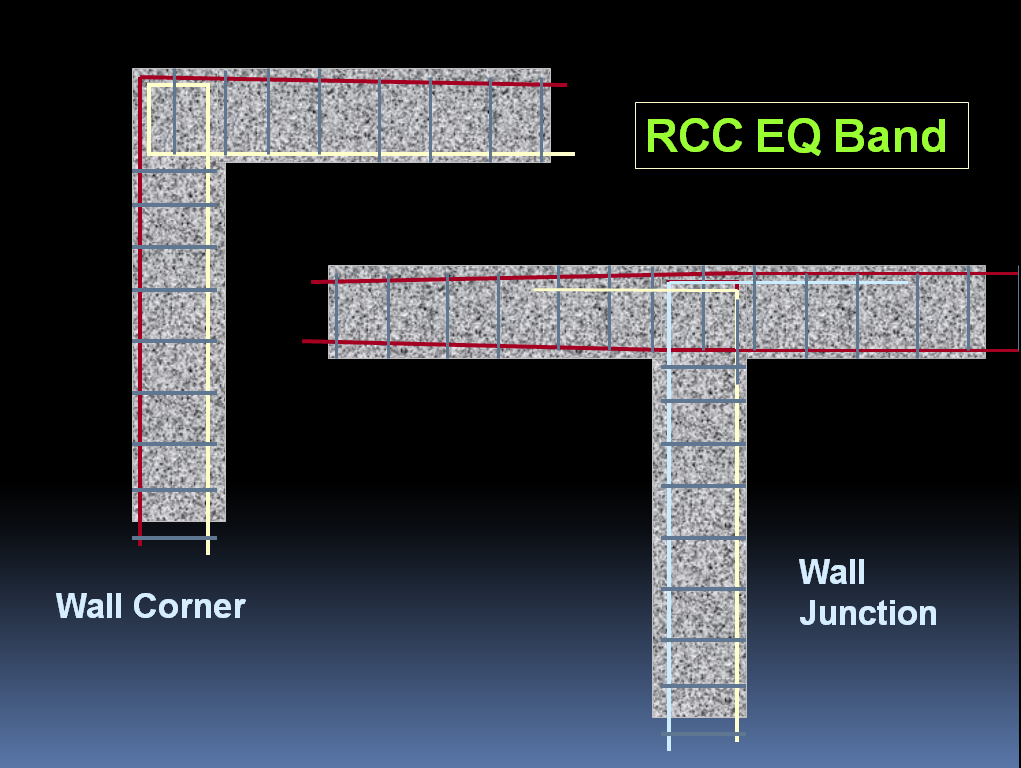

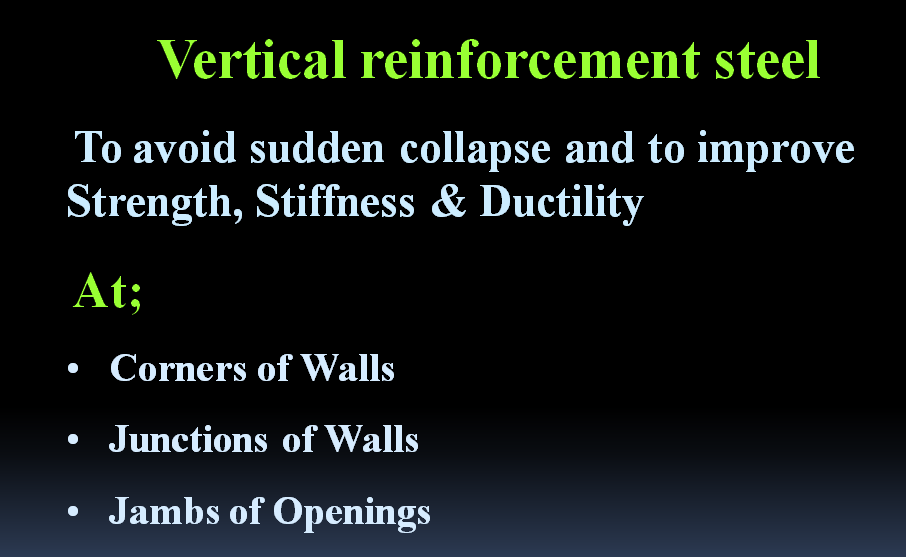

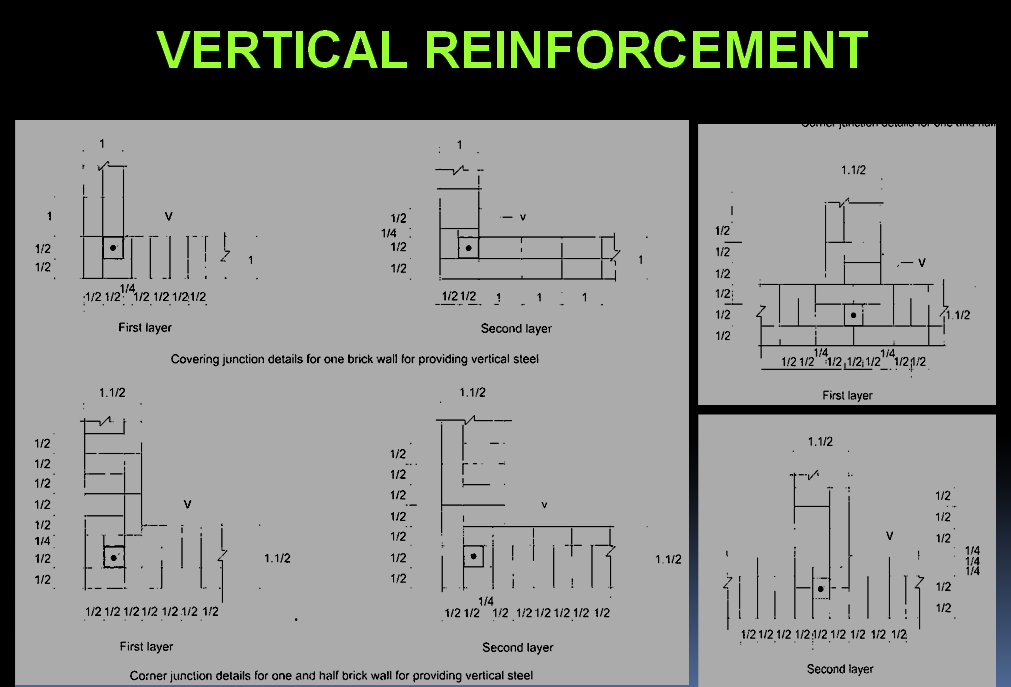

| Earthquake Resistant Housing |

| Earthquake Resistant Housing Propagation: |

| The Appropriate Technology Centre, Sundernagar is actively associated in creating awareness amongst the common masses and training technical manpower namely; Junior Engineers, Technical Assistants, rural masons and carpenters etc. for construction of earthquake resistant building/houses in the State. |

Himachal Pradesh is highly vulnerable to prominent natural disasters. Earthquakes are the major natural disasters that pose a severe threat to Himachal Pradesh. Most of the area of the State falls in two high Seismic Zones i.e., Zone V and IV. As per the seismic zoning map of the State, mainly Chamba (53.2%), Hamirpur (90.9%), Kangra (98.6%), Kullu (53.1%) and Mandi (97.4%) have 53 to 93.6% of their area liable to severest design intensity of MSK IX or more, the remaining area of these districts being liable to next severe intensity VIII. Two districts Bilaspur (25.3%) and Una (37.0%) also have substantial area in MSK IX and rest in MSK VIII. As a whole, nearly about 31.94 % of the total geographical area of the State fall under high seismic risk zone

Effect of Earthquake Magnitude

• Earthquake is sudden, violent movement of the earth’s surface from the release of energy in the earth’s crust.

• Richter scale or modified Mercalli Intensity Scale is commonly used to denote the intensity of earthquake.

• 3.5 to 5.4 magnitude of earthquake on Richter scale (MM scale III & IV) often felt by the people but hardly cause any damage to the structure.

• 6.1 to 6.9 magnitude of earthquake on Richter scale (MM scale VII & VIII) can be destructive in areas spread up to 100 Km distance.

• 7 to 7.9 magnitude of earthquake on Richter scale (MM scale IX & X) is termed as major earthquake and can cause serious damage over large areas.

• 8.0 or greater magnitude of earthquake on Richter scale ( MM scale X –XII ) is a great earthquake and can cause severe damage over several hundred Km across.

Earthquake is associated with the number of uncertainties and unpredictable variables. There is always a possibility that a severe earthquake could adversely affect a structure designed and constructed to the state-of-art knowledge. It is not intended in the earthquake standards to lay down regulations so that no structure shall suffer any damages during earthquakes of all magnitudes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Rainwater Harvesting Technology |

| 1) Rainwater Harvesting through Ferro-Cement Technology: |

| Roof Rain Water Harvesting provides a lot of scope and potential for long-term use of water on site at water scarcity areas in the State both for domestic and agriculture use. It is cost effective tool for meeting out the water demand during the lean periods. There is sufficient rainfall annually to permit the collection of adequate amounts of water on the roofs available in the State. For the rainwater harvesting the storage tank can be constructed from various technologies namely; brick masonry, stone masonry, Synthetic Polymers, Reinforcement concrete and steel etc. Upto 5m3 capacity ferro-cement tanks can be constructed which is an immediate solution for the collection of Roof Top Rainwater. |

Under Construction Ferro_Cement Tank

|

Under Construction Water Tank

|

Constructed Ferro-Cement Tank

| | 2) Rainwater Harvesting through LDPE Ponds: |

In drought prone areas Rain water can be collected by constructing LDPE Ponds in the farmer’s fields for use in agriculture fields. A simple technological intervention before the onset of the monsoon can rectify the problem. Lining the pond or tank with a layer of low density Polyethylene film (LDPE) is simple techniques which conserve water and ensure better water management in areas of limited water resources.

The Appropriate Technology Centre, Sundernagar is propagating this technology by construction of LDPE Lined Ponds on demonstration basis at water scarcity areas for the benefit of the farming communities in the State. The programme is being implemented through Block Development Officers / Panchayats in the State. |

Low Cost LDPE Pond

|

Low Cost LDPE Pond

|

Low Cost LDPE Pond

| | | | | |

| | | |

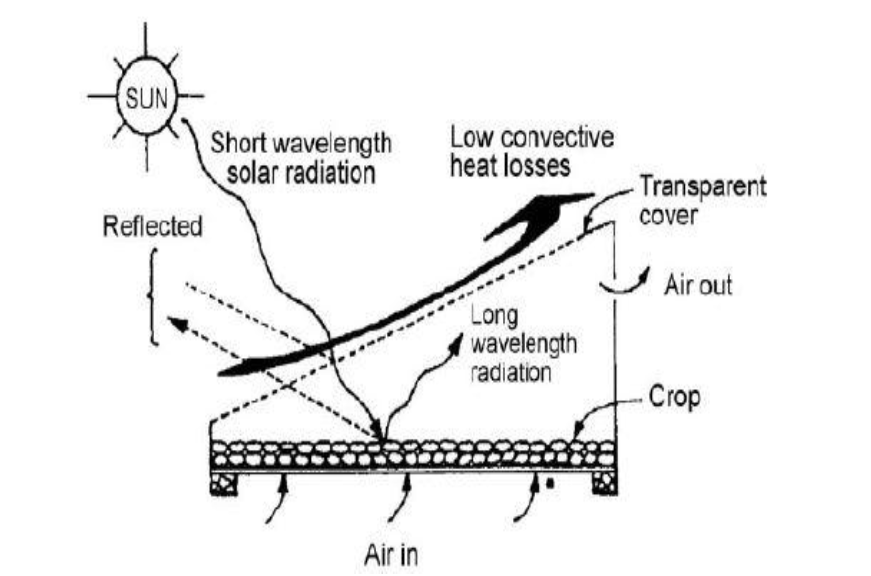

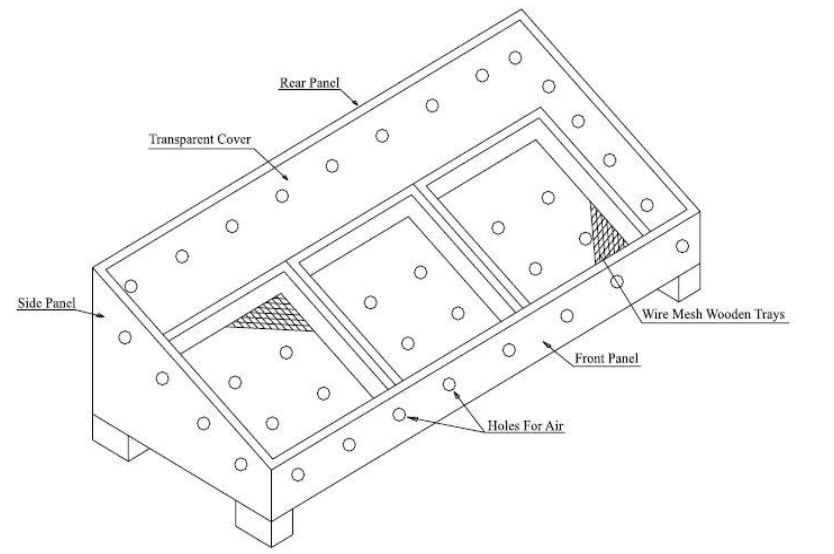

| | | Solar Dryers | | H.P produces vegetables, fruits, seeds etc. which has potential for drying and can be consumed during lean periods. The general traditional practices for drying is wild apricots, apricots, apples, pears, wild pomegranate, almonds, chilgoza cones, tomatoes, peas, chilies maize etc. They are openly dried during the day on rooftops or in farmyards which are spoiled/infected by the flies and are unhygienic for consumption of the mankind. | | The conventional sun drying takes longer time period /duration for drying of the eatables in the open. Solar dryers are the best option for reducing the time scale as well as retention of hygienic conditions from health point of view. | |

Direct solar dryers expose the substance to be dehydrated to direct sunlight. Historically, food and clothing was dried in the sun. A direct type of solar dryer has a black absorbing surface which collects the light and converts it to heat; the substance to be dried is placed directly on this surface. These driers may have enclosures; glass covers and/or vents to in order to increase efficiency.

|

Working of Solar Dryer

|

Drawing of Solar Dryer

|

Carpenters Fabricating Solar Dryers

|

Carpenters Fabricating Solar Dryers

|

| | | | | | |

|

Solar Passive Housing Technology

|

|

The Appropriate technology Centre, Sundernagar is propagating solar passive housing technology which is an environment friendly and economically viable technology in which the Site planning and movement of Sun in summer and winter is considered to create comfortable living conditions of the houses in the State. The Govt. of H.P has made solar passive house construction mandatory in all Govt./Semi-Govt. buildings in the State after successful implementation of the solar passive housing programme in the State.

|

|

The various components in a passive solar housing are arranged in such a way that maximum solar heat is conserved /stored and distributed for healthy living in the building/houses. The adoption of Solar passive heating or cooling technology in the design of buildings in India will not only reduce the large consumption of fossil fuels and electricity for space heating, cooling and day lighting during winter, but will also result in considerable saving of exchequer in the longer run. Solar Passive Housing Technology is used for heating as well as cooling of the buildings/houses. A passive solar house provides cooling and heating to keep the home comfortable without the use of mechanical equipment during summer and winter.

|

|

The Himachal Pradesh Council for Science Technology and Environment, is imparting training for capacity building of the Junior Engineers, Architects, Technical Assistants, Rural masons/artisans for construction of passive solar houses / buildings at Appropriate Technology Centre, Sundernagar as well as in the fields in the State.

|

Building Centre constructed with HUDCO

|

Indira Awas Yojna Model House

|

|

|

Thermosyphonic Air Heating Panel

|

Trombe wall in Govt. Polytechnic,Sundernagar

|

|

|

|

|

|

|

|

|

Domestic Waste Water Recycling System |

|

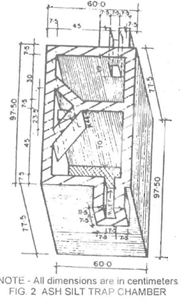

This system consists of an ash/silt trap chamber and a bore hole. The ash silt trap chamber is rectangular in shape having· 7.5 cm thick wall of burnt brick laid in 1:6 cement sand mortar and is constructed near waste water outlet. It is divided into two compartments by a 7.5 cm thick wall and is covered with a R.C.C. or reinforced brick lid.

|

|

It is divided into two compartments by a 7.5 cm thick wall and is covered with a R.C.C. or reinforced brick lid. The sizes of first and second compartment are made as 40X45x70 cm and 30x45x70 cm respectively. Triangular ducts 8x8 cm in size and 46 cm deep are made in corners adjacent to each other in both compartments, diagonally opposite to inlet.

|

|

A hole is left in the partition wall 19.0 cm below the top of the duct portion to provide connection between the two ducts. The second compartment is filled with 4 cm size brick ballast. In the first compartment, heavier particles of silt and ash, flowing with waste water, settle down, and floating and greasy materials get trapped .

|

The water having only colloidal and suspended particles rises through the duct of the first compartment and flows to the bottom of the second compartment through the duct. The suspended and colloidal particles get stuck to the brick ballast and only clear water is allowed to flow into the bore hole for final-disposal underground.

|

|

Water being used for cleaning of utensils is waste water which generally is not used for any purpose and creates pollution of the environment around the houses in both villages as well as urban areas and become a breeding ground for insects/pests/flies etc. The Appropriate Technology Centre, Sundernagar in order to make use of the so called waste water has started popularizing use of waste water recycled for other domestic use like cleaning of the house, its premises, toilets and for kitchen gardening etc. The training is imparted for construction of waste water recycled units by the ATC, Sundernager to JEs , Technical Assistants, rural artisans etc. for propagation of the technology of reuse of waste water generated from kitchen for cleaning of house, toilets and gardening etc.

|

Training Program for Engineers and Masons

|

Drawing Detail of Waste Water Recycling System

|

Waste Water Recycling System

|

|

|

|

|

|

|